PRODUCT CENTER

Product Classification

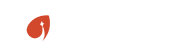

JL-2816 channel type leather machine

1. Three-stage structure design, which integrates typesetting, cutting and receiving, can work synchronously, so that leather cutting can be done in one step, which is conducive to the highest efficiency of the equipment and the maximum energy saving.

2, the use of high-definition projection system, can clearly identify the leather defects, shape, size, leather grain direction, etc. The intelligent discharge system can partition and grade the leather material, make the best use of it, and effectively improve the utilization rate of leather material. The utilization rate of single leather material is as high as 87%.

3, the use of partition adsorption system design, can be better and more stable adsorption processing materials, to avoid the process of material displacement.

4, the use of automatic feeding mode, greatly improve the efficiency of machine processing, reduce the workload of workers.

5. Servo-controlled trajectory walking can accurately realize zero-spacing cutting, avoid missing cutting and wrong cutting, have strong stability and cutting accuracy as high as ± 0.1mm.

6. Infrared grating protection to ensure the safety of workers.

Learn more

2, the use of high-definition projection system, can clearly identify the leather defects, shape, size, leather grain direction, etc. The intelligent discharge system can partition and grade the leather material, make the best use of it, and effectively improve the utilization rate of leather material. The utilization rate of single leather material is as high as 87%.

3, the use of partition adsorption system design, can be better and more stable adsorption processing materials, to avoid the process of material displacement.

4, the use of automatic feeding mode, greatly improve the efficiency of machine processing, reduce the workload of workers.

5. Servo-controlled trajectory walking can accurately realize zero-spacing cutting, avoid missing cutting and wrong cutting, have strong stability and cutting accuracy as high as ± 0.1mm.

6. Infrared grating protection to ensure the safety of workers.

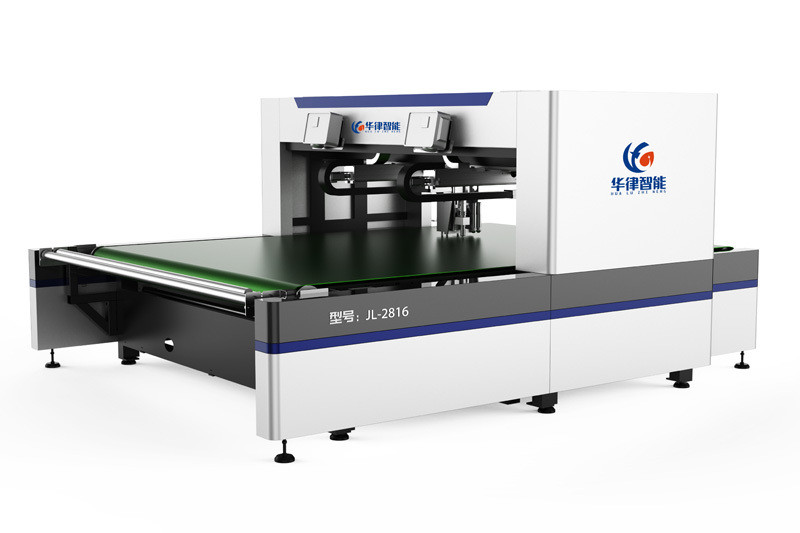

JL-2516 leather cutting machine

1. The common edge cutting of the front and rear plates can be achieved, which greatly improves the material utilization rate and maximizes the cutting benefit.

2. Automatic feeding, continuous cycle cutting mode can run stably for 24 hours.

3, suitable for all kinds of flexible material cutting, can be leather, leather, cloth and other flexible materials for single-layer and multi-layer perfect automatic cutting.

4. It has the dual function of pneumatic knife and electric knife. The main cutting materials are: microfiber, canvas, pig leather, large cowhide and other flexible materials.

5. The key moving parts adopt first-line brand products, which are more wear-resistant and more stable, and improve the life of the machine.

6. Servo-controlled trajectory walking can accurately realize zero-spacing cutting, avoid missing cutting and wrong cutting, have strong stability and cutting accuracy as high as ± 0.1mm.

7. Infrared grating protection to ensure the safety of workers.

Learn more

2. Automatic feeding, continuous cycle cutting mode can run stably for 24 hours.

3, suitable for all kinds of flexible material cutting, can be leather, leather, cloth and other flexible materials for single-layer and multi-layer perfect automatic cutting.

4. It has the dual function of pneumatic knife and electric knife. The main cutting materials are: microfiber, canvas, pig leather, large cowhide and other flexible materials.

5. The key moving parts adopt first-line brand products, which are more wear-resistant and more stable, and improve the life of the machine.

6. Servo-controlled trajectory walking can accurately realize zero-spacing cutting, avoid missing cutting and wrong cutting, have strong stability and cutting accuracy as high as ± 0.1mm.

7. Infrared grating protection to ensure the safety of workers.

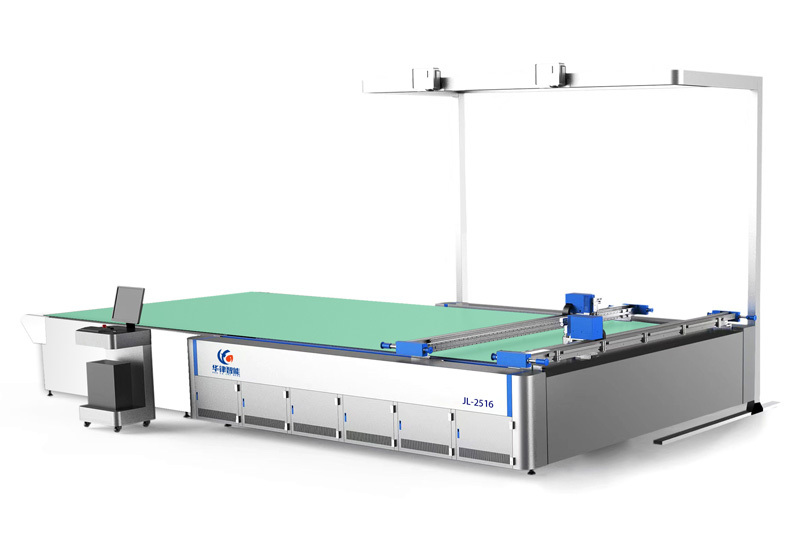

JL-2832 big leather cutting machine

1. Use the electric knife function. The main cutting materials are: large cowhide, two-layer leather and pig leather.

2. Servo-controlled trajectory walking can accurately realize zero-pitch cutting, avoid missing cutting and wrong cutting, have strong stability and cutting accuracy as high as ± 0.1mm.

3, the use of automatic feeding mode, greatly improve the efficiency of machine processing, reduce the workload of workers.

4. The key moving parts adopt first-line brand products, which are more wear-resistant and more stable, and improve the life of the machine.

5. The use of fabrics can be accurately tracked according to the layout diagram to achieve the purpose of saving fabrics.

6. Infrared grating protection to ensure the safety of workers.

Learn more

2. Servo-controlled trajectory walking can accurately realize zero-pitch cutting, avoid missing cutting and wrong cutting, have strong stability and cutting accuracy as high as ± 0.1mm.

3, the use of automatic feeding mode, greatly improve the efficiency of machine processing, reduce the workload of workers.

4. The key moving parts adopt first-line brand products, which are more wear-resistant and more stable, and improve the life of the machine.

5. The use of fabrics can be accurately tracked according to the layout diagram to achieve the purpose of saving fabrics.

6. Infrared grating protection to ensure the safety of workers.

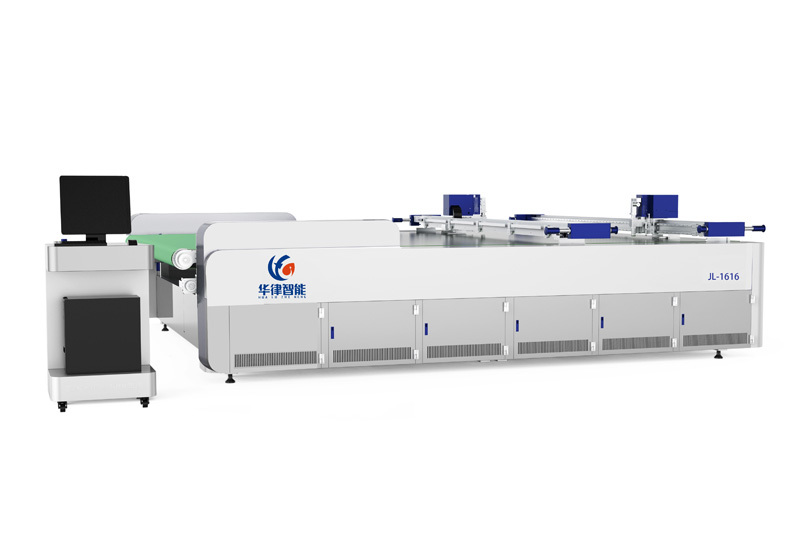

JL-1616 intelligent multi-layer cutting machine

1. Mainly applicable to the cutting of microfiber, cloth and PVC.

2, the use of automatic feeding mode, greatly improve the efficiency of machine processing, reduce the workload of workers.

3. The cutting efficiency is fast, and the maximum cutting speed can reach 1500 mm/s.

4. High cutting accuracy, up to ± 0.1mm.

Learn more

2, the use of automatic feeding mode, greatly improve the efficiency of machine processing, reduce the workload of workers.

3. The cutting efficiency is fast, and the maximum cutting speed can reach 1500 mm/s.

4. High cutting accuracy, up to ± 0.1mm.

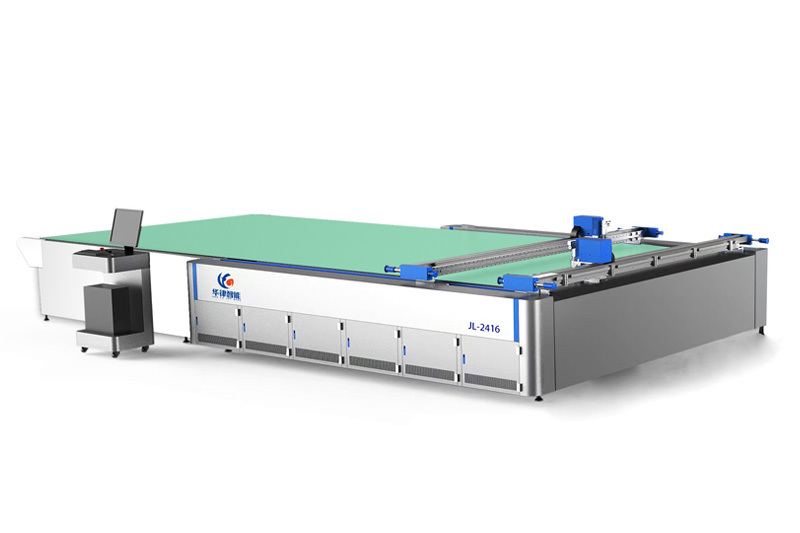

JL-2416 single-head multi-layer cutting machine

1, the use of pneumatic knife cutting method, mainly used for ultra-fiber, cloth, PVC cutting.

2. Servo-controlled trajectory walking can accurately realize zero-pitch cutting, avoid missing cutting and wrong cutting, have strong stability and cutting accuracy as high as ± 0.1mm.

3. The cutting efficiency is fast, and the maximum cutting speed can reach 1500 mm/s.

4, the use of automatic feeding mode, greatly improve the efficiency of machine processing, reduce the workload of workers.

5. Infrared grating protection to ensure the safety of workers.

Learn more

2. Servo-controlled trajectory walking can accurately realize zero-pitch cutting, avoid missing cutting and wrong cutting, have strong stability and cutting accuracy as high as ± 0.1mm.

3. The cutting efficiency is fast, and the maximum cutting speed can reach 1500 mm/s.

4, the use of automatic feeding mode, greatly improve the efficiency of machine processing, reduce the workload of workers.

5. Infrared grating protection to ensure the safety of workers.